Increased occupational safety and reduced idling times

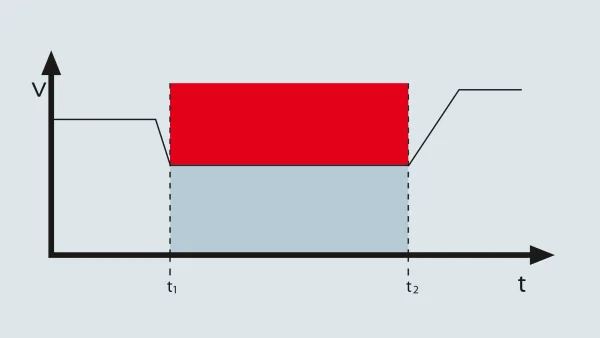

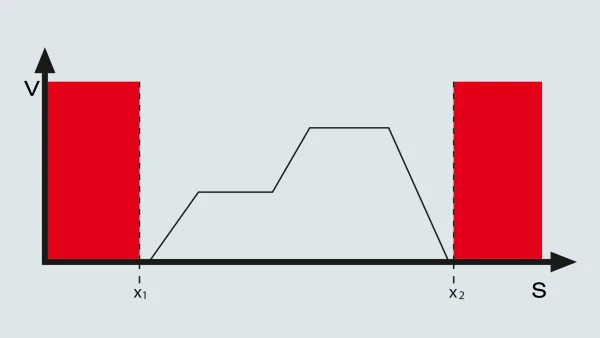

System controls that monitor the production process instead of switching it off can be installed in the system in accordance with the EC Machinery Directive 2006/42/EC and EN ISO 13849-1 standard, which are intended to minimize the risk posed to people by technical equipment. The control systems applied must satisfy the relevant requirements regarding safety and performance level.

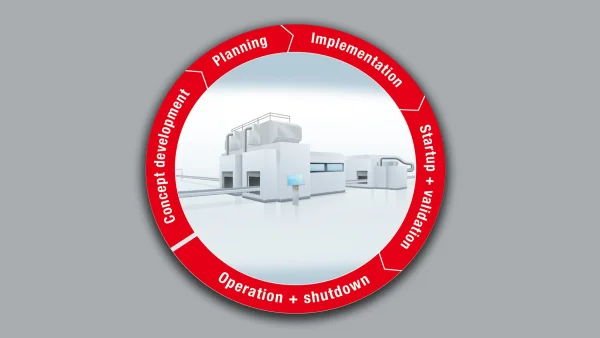

Not only is the concept of “functional safety” significant for employee safety, but it can also significantly increase the productivity of the machines and systems. This is why SEW‑EURODRIVE is investing in flexible solutions with safetyDRIVE. Flexibility is key: the modular safety technology components or the safety technology integrated directly into the drive technology are individually selected and adapted according to the application and task.

Your benefits

-

Functionally safe drive technology

For trouble-free and safe operation of machines and systems -

Avoid workplace accidents

and safeguard staff safety -

Increased productivity

with our safety products and services -

Reduced costs

thanks to a reduction in safety zones -

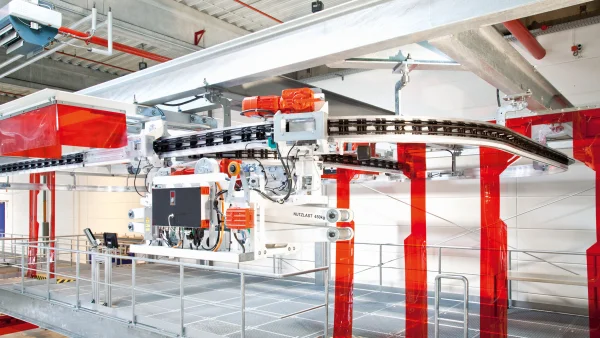

Covers many branches of industry

because we have developed our safetyDRIVE drive technology to cater for a range of different requirements, industries and system structures

Feel free to contact us!

Do you have more questions about SEW-EURODRIVE or need some advice from us? Just send us a message with your questions.